Powerful Technologies Unlock the Industrial Internet Ecosystem

The global Industrial Internet is currently at a critical stage of development and large-scale expansion. Developing the Industrial Internet represents a new route for countries to gain a dominant position in industries and reshape their industrial systems. IP technologies, such as 5G, F5G, and intelligent cloud-network, are important steps in the evolution of next-gen information technologies, while the Industrial Internet can offer key support for the fourth industrial revolution. The combination of the two has risen towards the top of the agenda for many countries and industries in 2021, and this will continue for next few years.

China has already made remarkable achievements in platform cultivation and platform application for the Industrial Internet, developing over 100 platforms and connecting 73 million sets of industrial equipment. Various technologies have proved to be extremely powerful: Enterprises are able to connect people, machines, environments, and platforms with digital technologies for the in-depth integration of production systems, management systems, and network systems.

ICT empowerment: The Industrial Internet has entered a critical development phase

The development architecture of the Industrial Internet ecosystem is as follows: networks are the basis, platforms are the core, data is a key element, and security provides assurance. ICT is the foundation of this architecture. Strengthening network infrastructure is the first and most important task within the Industrial Internet Innovation and Development Action Plan (2021-2023) released by China’s Ministry of Industry and Information Technology (MIIT) in January 2021.

For networks, next-generation ICT provides high bandwidth, low latency, high reliability, and security, making unmanned AGVs, AI detection, and remote control a reality. Compared with 4G, Wi-Fi, and traditional OT networks, what are the advantages of 5G, F5G, and intelligent cloud-network?

5G + Industrial Internet: Most factory facilities are connected through industrial wired networks and Wi-Fi networks. The inflexibility of such wired networks, coupled with the potential for high Wi-Fi latency, create multiple challenges in reliability and synchronization. Instead of attempting to overcome challenges posed by traditional industrial technologies, factories should look to adopt high-speed and low-latency 5G connections that can drive the digital transformation of production lines.

F5G + Industrial Internet: Gigabit optical networks based on 10G PON and Wi-Fi 6 are seeing rapid development in relation to home scenarios and are also providing strong support for various new applications in Industrial Internet scenarios.

In traditional factory networks, a lot of electromagnetic interference exists and most equipment is customized by various international manufacturers. Different communications protocols have resulted in information silos. Industrial PON is a standardized product adapted from traditional PON, which is highly compatible with industrial applications.

It's highly localized and highly reliable, and can lay a solid network foundation for enterprise digitalization.

Intelligent cloud-network: MPLS networks used in traditional industrial scenarios have complex configurations and cannot provide deterministic latency for key services. Therefore, the industry recommends IPv6+ (SRv6) for constructing industrial extranets. As an intelligent IP network technology for the cloud era, IPv6+ meets requirements for flexible networking, fast service provisioning, intelligent route selection, simplified network O&M, and differentiated assurance.

In 2021, Huawei, together with China Academy of Information and Communications Technology (CAICT) and other organizations, released the White Paper on Prospects of a Solid Foundation for the Network System. According to the white paper, "connected devices and IP networks" will enable the flexible, end-to-end networking of IT and OT, creating a network base for a fully connected Industrial Internet. This will vastly increase available data and computing power, which is crucial for the Industrial Internet to develop rapidly.

Benchmarks show the Industrial Internet’s true value

All parties in the industry are collaborating to meet industrial IoT requirements in different scenarios, and have developed a number of successful ICT + Industrial Internet cases in smart manufacturing, smart campus, and smart ports. This work is helping enterprises achieve comprehensive digital transformation and development.

In June 2021, SANY Heavy Industry launched its first fully connected 5G factory in Beijing. The factory has implemented 5G applications across more than 30 scenarios in eight categories, including manufacturing, visual management, and smart logistics. New applications throughout the manufacturing process have helped eliminate wires, phase out equipment rooms, reduce the need for manual labor, and implement data-driven intelligent applications.

At the company's Nankou Industrial Park in Beijing, the coordination of multiple AGVs has been realized by replacing traditional laser navigation with visual navigation, reducing costs by more than 80%. With 5G technology, only one person is required to complete cutting with laser technology. Without 5G technology in place, this would require dozens of people. Therefore, efficiency has been improved more than tenfold.

In May 2021, I visited JOMOO Group's 5G smart industry park, a high-end kitchen and bathroom brand. Since 2019, JOMOO has been working with carriers to implement 22 innovative applications in nine scenarios, including production equipment management, production line energy consumption management, smart warehousing, and automatic quality inspection, all using 5G+MEC (edge computing) technologies.

These innovative applications have allowed JOMOO to reduce labor costs by 20% and improve management efficiency by 20%. The product quality from its production lines is continuously improving, while the rate of defective products has been reduced by 5%. The company has also reduced energy consumption by 7% and operating costs by 8%. In addition, JOMOO's product R&D cycle has been shortened by 15 days per year.

In June 2021, Yongcheng Coal & Electricity Holding and Huawei launched China's first commercial F5G-based mine. Supporting fifth-generation N00 coal mining technology, F5G acts as a bridge between data systems in coal mines and provides a fully sensing, fully connected, and fully intelligent experience, laying a solid foundation for the creation of safe and intelligent mines.

The F5G-based mine uses a large number of passive optical transmission nodes to replace traditional active equipment, reducing the number of anti-explosion nodes by 40%. This ensures electrical safety, while reducing the investment required for anti-explosion equipment. The intelligent diagnosis function can accurately locate faults to within meters, reducing the amount of time a worker needs to spend in the mine dealing with faults by about 90%.

As a major joint venture in steel manufacturing in China, Masteel Group needs to link information silos and establish a centralized operation control center for the entire business system. To do so, it has adopted the intelligent cloud-network solution to build an IP network that can cover the entire company. This comes with numerous advantages such as intelligent routing, latency assurance, and one network for multiple uses.

The transport network allows Masteel Group's various centralized systems to remotely manage product lines, while flexibly supporting multiple types of business across product lines and subsidiaries. This facilitates centralized operation rooms, completely automated operations, entirely remote O&M, and exclusively online services, meeting the group's development requirements for the next five to ten years.

In April 2019, Ningbo-Zhoushan Port, the busiest in the world by cargo throughput, initiated the 5G smart port project. The port has already addressed many technical issues related to 5G base stations, core networks, data communications, devices, cameras, PLCs, and industrial PCs. Now, the port's upper limit for 5G latency is less than 50 ms, while the average latency sits at around 10 ms.

Supported by a 5G network, the Ningbo-Zhoushan Port realizes the remote control of gantry cranes, increasing loading and unloading efficiency by 20%, which is expected to equal a 50% cut in manual labor costs. Most importantly, drivers do not need to sit in small cabs 30 meters above ground and work continuously. Instead, they have seats in remote offices, from where they control the cranes. The work environment has been transformed from a cramped "box" to a comfortable air-conditioned room.

The industry ecosystem is nearing completion, and applications are expected to see large-scale development.

Although China's Industrial Internet has made significant breakthroughs and progress, the digital industry upgrade is still in its infancy. Greater efforts and collaboration between all stakeholders are required before the integration of digital technologies and the Industrial Internet can be truly realized.

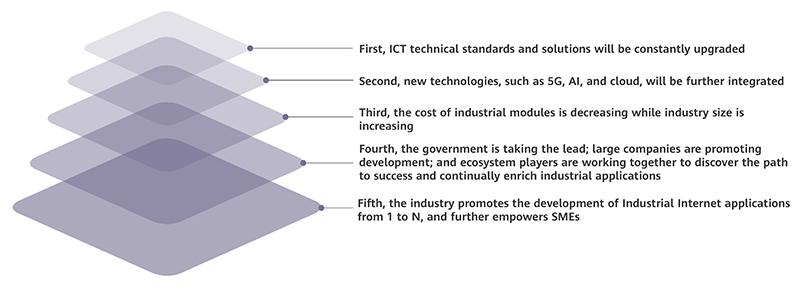

As ICT and industrial application know-how develop, I believe that the future Industrial Internet will evolve in the five following ways.

First, ICT technical standards and solutions will be constantly upgraded. The communications technologies currently used in industrial manufacturing are varied, enclosed, and limited by their own distinct deficiencies. This makes it difficult to connect different pieces of industrial equipment to one network, let alone a global network.

Some sectors have acted to address this issue. For example, smart port communications standards and smart coal mine 5G standards are currently under development and will soon be released.

The ICT industry is upgrading technical solutions based on industrial needs. For example, to meet the requirements of the coal industry, 5G equipment must be adapted and designed in a way that makes it anti-explosion. For example, its transmit power should be limited to less than 6W to meet the safety requirements of underground mining. This year, China Mobile and China Unicom launched the 5G-Advanced action plan, which has greatly enhanced 5G capabilities in terms of uplink and downlink user-perceived rates, high-precision positioning, connection density, and perception.

Second, new technologies such as 5G, AI, and cloud will be further integrated. Cross-industry cooperation has been a challenge to the development of Industrial Internet for many years. To address this, the industry has delved into core operational technology (OT) scenarios in factories to accelerate digital transformation in terms of edge-cloud collaboration, cloud-network collaboration, and all-scenario AI, while also exploring innovation through integration with technologies like blockchain, AR/VR, and holography. These efforts aim to promote collaboration between 5G/F5G, cloud, AI, and IoT to support various industrial scenarios and applications.

Third, the cost of industrial modules is decreasing while industry size is increasing. Currently, over 60 5G modules exist in the industry. However, there are more than 1400 types of 4G modules, which are also available at lower prices. As a result, existing industrial terminals for 5G cannot meet the market requirements of numerous industries. As collaboration between chip, module, and industrial terminal vendors increases, and innovation accelerates, the number of types of 5G modules will increase and prices will greatly decrease.

Fourth, the government is taking the lead; large companies are promoting development; and ecosystem players are working together to discover the path to success and continually enrich industrial applications. The convergence of ICT and Industrial Internet has raised higher requirements on the professionalism of production processes. However, existing technologies, products, and solutions haven’t yet linked up to form a complete industry ecosystem in some stages of the industrial manufacturing process. In view of this, all Industrial Internet players, including the government, companies in vertical industries, ICT companies, ISVs, and industrial integrators, are working to provide a larger stage for cross-industry collaboration and application innovation. MIIT has held the "Blooming Cup" 5G Application Contest annually since 2018, and the number of submissions it has received increased from 300 in 2018 to more than 4,000 in 2020. The Hubei government has led the establishment of the 5G Industry Alliance, and other local governments and ministries have also built a number of 5G application innovation centers. In addition, the Commercial Aircraft Corporation of China formed a 5G industry alliance and created an open platform for AI innovation.

Fifth, the industry promotes the development of Industrial Internet applications from 1 to N, and further empowers SMEs. Large industrial manufacturing companies have sufficient capital and talent reserves, and the conditions for promoting the development of the Industrial Internet are relatively mature. However, tens of millions of SMEs in China find themselves in an awkward position, where they are willing to adopt the Industrial Internet but unable to do so.

Therefore, leading carriers and industrial enterprises are helping SMEs migrate millions of industrial devices to the cloud through the iteration and upgrading of the Industrial Internet platform. At the same time, they are working together to explore a cooperation, sharing, and integration mechanism for Industrial Internet data. For example, the Fujian ceramic Industrial Internet cloud platform, jointly launched by Xiamen Nistone Technology and China Telecom, has allowed JOMOO to go digital, while also improving the quality and efficiency of China's ceramic industry and helping it go intelligent.

In the future, we hope that provincial and municipal governments, industry organizations, and industry-leading companies will work together to build ICT infrastructure and Industrial Internet public service platforms. In addition to promoting industrial application innovation and interdisciplinary talent cultivation, we should push for ecosystem development, and expand beyond the traditional business model of connectivity to promote further innovation and integration of technology and markets. This will be integral to the digitalization and intelligent upgrade of all industries.

}})